Chemical protection clothing is a vital component of personal protective equipment (PPE) designed to shield workers from exposure to hazardous chemicals in the workplace. This specialized clothing serves as a crucial barrier, preventing direct contact with harmful substances and minimizing the risk of skin absorption, inhalation, or ingestion of toxic chemicals. Understanding the basics of chemical protection clothing is essential for ensuring worker safety and health in environments where chemical hazards are present.

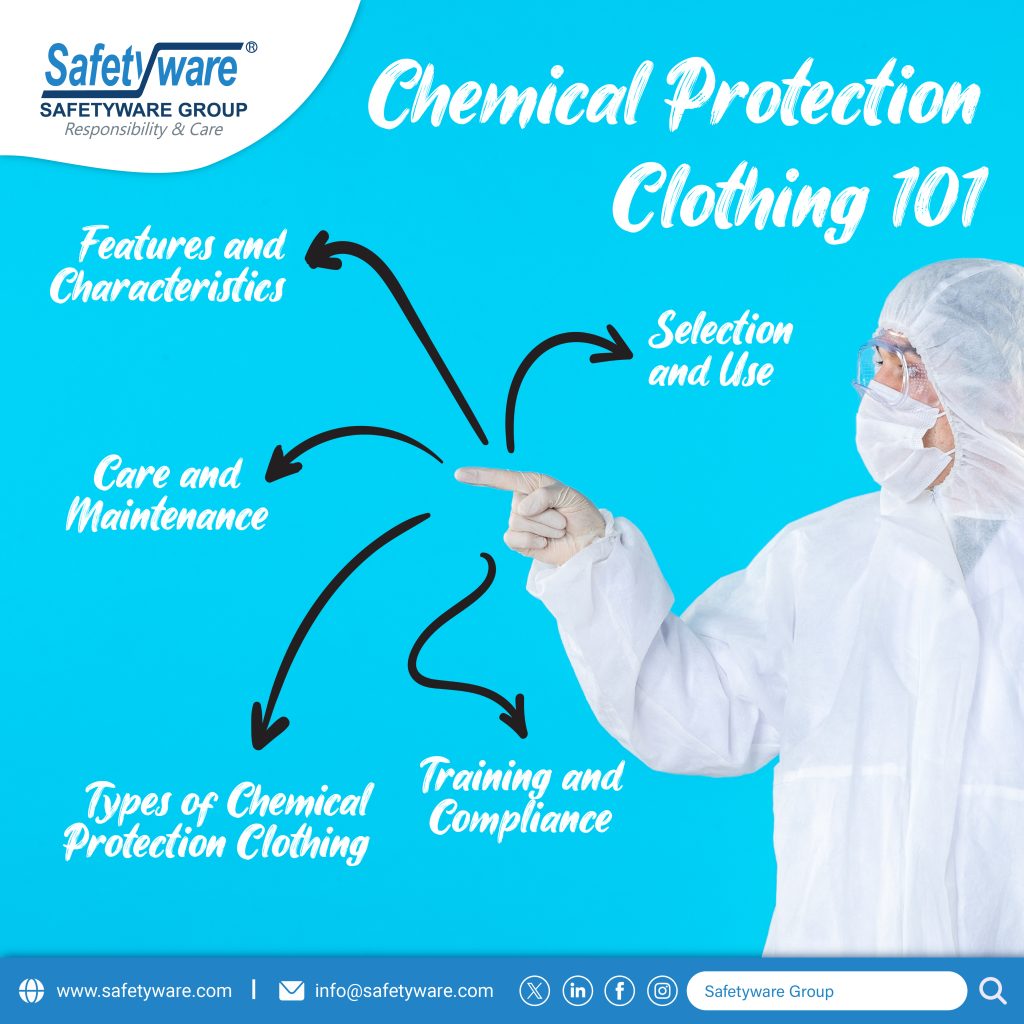

Types of Chemical Protection Clothing:

Chemical protection clothing comes in various forms to suit different levels of protection and specific workplace requirements. Common types of chemical protective clothing include coveralls, suits, aprons, gloves, boots, and hoods. These garments are typically made from materials such as butyl rubber, neoprene, PVC, Tyvek, or other specialized fabrics known for their resistance to a wide range of chemicals.

Selection and Use:

Selecting the appropriate chemical protective clothing is crucial and should be based on the type of chemicals present, their concentration, and the duration of potential exposure. It is essential to choose clothing that offers the necessary level of protection while ensuring comfort and ease of movement for the wearer. Proper fitting, sizing, and compatibility with other PPE items, such as respirators and gloves, are also important considerations.

Features and Characteristics:

Chemical protection clothing is designed with specific features to enhance safety and usability. These features may include chemical resistance, durability, comfort, breathability, sealed seams, closures, and ventilation systems. High-quality protective clothing is engineered to withstand chemical splashes, spills, and exposure while allowing the wearer to perform tasks effectively and comfortably.

Care and Maintenance:

Maintaining chemical protection clothing is essential to preserve its effectiveness and prolong its lifespan. Proper care practices, such as regular cleaning, inspection for damage, appropriate storage, and timely replacement of worn or damaged garments, are crucial to ensure continued protection for workers.

Training and Compliance:

Training employees on the proper selection, use, limitations, and maintenance of chemical protection clothing is key to ensuring its effectiveness. Workers should be familiar with donning and doffing procedures, as well as any specific guidelines for the use of protective clothing in their work environment. Compliance with relevant regulations and standards is essential to meet safety requirements and protect workers from chemical hazards.

Conclusion:

In conclusion, chemical protection clothing is a fundamental element in safeguarding workers against the risks associated with hazardous chemicals in the workplace. By understanding the types, selection criteria, features, care practices, and compliance requirements related to chemical protection clothing, organizations can enhance workplace safety, mitigate risks, and prioritize the well-being of their employees in environments where chemical exposure is a concern. Investing in proper chemical protection clothing and providing comprehensive training on its use can significantly contribute to a safer and healthier work environment.